Beer Foam Properties - The Impact of Recipe on Stability Enhancement

- Oliver Kitson

- May 14, 2021

- 4 min read

The head of a beer, when served in a glass, forms a major part of how a consumer will visually assess the quality of the product. Other visual factors influencing customer perception of a beer are effervescence, colloidal stability or clarity, and colour. A consumer will judge the quality of beer foam based on a number of different categories including stability, size of bubbles, lacing and mouth feel. With the amount of head being present on beer served by the glass arguably diminishing in bars, as people desire less foam (and thereby receiving more beer and a greater value for money), it is becoming increasingly important that the foam has greater stability and longevity. Customers prefer a white, creamy head that consists of small bubbles, which clings to the glass as the beer is drunk. Foam is also important as it acts as a gas exchange layer where aroma molecules from the beer, such as hop derived compounds, are transferred to the air and subsequently detected by the drinker.

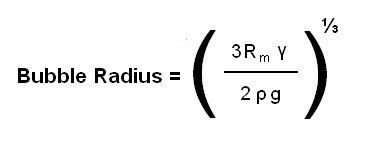

Foams are a complex dispersion of gaseous bubbles trapped within a liquid. The ratio of gas to liquid in the foams of drinks is generally between 50% and 90%, with fractions above approximately 75% usually resulting in the bubbles distorting and deforming one another’s shape. Foams are dynamic systems and as soon as bubbles form, via nucleation, changes in structure begin to occur. Smaller bubbles may dissolve, while the bigger ones will grow in size by diffusion of gas through the continuous phase, known as Ostwald ripening. Although beer is supersaturated with gas it will not form bubbles unless nucleation sites are present, instead without them the gas would simply leave the aqueous phase at the liquid surface and pass into the air. A number of different things may provide a nucleation site, including etching of glassware, small particles or even cavitation caused by instantaneous vacuum formation between the liquid and container produced upon agitation. The smaller a nucleation site is the better, as this results in the formation of smaller bubbles and therefore a finer foam. This is highlighted by the equation in figure 1 where the relationship between nucleation site radius and bubble size is described. The method of dispense also has a significant impact on foam quality.

Figure 1. Equation of the relationship between the radius of a nucleation site, the properties of the fluid in which they are formed and the size of the resulting bubbles. Rm = nucleation site radius (m), γ = surface tension (mN.m-1), ρ = fluid density (kg.m-3), g = gravitational acceleration (9.8 m.s-2). (Adapted from Evans and Bamforth 2009)

Devices such as widgets in canned beer and sparklers on pumps became very prevalent at the end of the nineties as a means to assist in the formation of smaller bubbles and creamier foam. The type of gas employed by the brewer will also have a dramatic effect on the mouth feel of the foam. Nitrogen gas is being increasingly used in conjunction with carbon dioxide in beer as it has a lower partial pressure and therefore forms smaller bubbles and a finer foam.

Once developed bubbles will begin to cream, constantly forming and replenishing a separate foam layer above the bulk of the liquid from which they have originated. As liquid drains from the foam into the bulk bubbles begin to distort one another, as they pack together more tightly, altering their shape from spherical to polyhedral. See figure 2. Finally lamellae between the bubbles will rupture over a period of time allowing bubbles to merge together, a process referred to as coalescence.

Figure 2. Formation of honeycomb like structure in foam by changes in bubble shape from spherical to polyhedral, due to drainage of liquid from the foam. (Adapted from Walstra 1989)

Numerous studies support that the head on a beer is stabilised mainly through the formation of peptide complexes. Such peptides include protein Z, lipid transfer protein 1 (LTP1, found in the aleurone of germinating grains and malt) and various different hordeins. These peptides originate from malt proteins, which have undergone many different chemical changes during the brewing process such as enzymatic cleavage and denaturation by high temperatures. Not all peptides in beer ameliorate foam to the same extent and some may in fact have a negative impact on stability. Generally hydrophobic peptides or glycoproteins of a relatively high molecular weight (>20 kDa) are considered to be the best foam promoters. These proteins are thought to stabilise foam by adsorbing to the gas-liquid interface where they promote steric and electrostatic stabilisation as well as conveying a greater structural integrity to the bubble lamellae through unfolding. This slows the rate of coalescence due to bubble rupturing and therefore the rate of foam decay. Hemicelluloses from both the malt acrospire and aleurone as well as dry hopping also have a foam stabilising effect as seen in figure 3.

Figure 3. Confocal micrograph of beer foam stained with acridine orange, emission measured at 520nm. Bubbles within the foam possess coronae of stained material surrounding them, indicating the presence of hemicelluloes supporting bubble lamellae.

The different parameters (particularly time and temperature) chosen in the processes of both malting and brewing (such as steeping, kilning, mashing, wort boiling and whirlpooling) will have a direct effect on the character of a beer. During these processes enzymatic breakdown and temperature based denaturation of proteins and polysaccharides occur, which dictate not only the, colour, flavour, and colloidal stability of the product but also its head retention. It is well known that the process of high gravity brewing and the utilisation of non-malt adjuncts (with the exception of wheat) to produce a beer more economically often has a negative impact on the foam quality of the finished product. This is due in part to a reduction in the overall hydrophobic polypeptide content of the beer produced.

Many other additional chemical species present in beer can alter foam quality, affecting stability, glass adhesion and protecting the head of a beer from foam negative compounds such as lipids and detergents. Naturally present foam promoting agents whose concentrations are dictated by a beer's individual recipe include; metal ions (such as calcium), ethanol, pectin and isohumulones (bitter flavouring compounds from hops). The particular concentrations of foam promoting agents in the final beer produced depend upon both the specific parameters employed in brewing and the type of ingredients employed. It is therefore a balancing act for brewers to tread in recipe design to achieve a suitable yield, colloidal stability, cost of goods and the desirable foaming properties sought by the consumer.

Comments